Savox On Intrinsic Safety

From the devastation in Tianjin, China to a random spark on your worksite, naval ship or oil refinary tomorrow, there’s one thing we know for certain: if it’s an unintentional explosion, nobody wants it.

Why We practice intrinsic safety

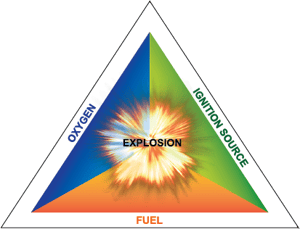

We know what causes explosions. Three ingredients are necessary - fuel, oxidizer and an ignition source. This is known as the “ignition triangle”. The three ingredients must be present at the same time, in the right conditions, and in correct proportion for ignition to occur. Once ignition does occur, a combustion wave can grow from the ignition and lead to explosion, which is essentially a combustion wave beyond control.

One example–the electric wall switch which could create a spark when operated and cause an explosion if the room or house where it is installed has a concentration of flammable gasses inside. Industries recognize the potential for explosions and have taken steps to minimize those caused by equipment used either in fixed or mobile installations.

| We know ways to prevent explosions. | |

|

Looking at the three components necessary for explosions, it’s easy to recognize that the component which can be most easily removed is the ignition source. There are about ten different distinctive technics to protect against ignition caused by electrical equipment. Among them are:

|

|

The protection concept used at Savox for products such as wired intercoms and two-way radio accessories is Intrinsic Safety (I.S.). Using technics such as conductive (static dissipative) enclosures, flame proofing and encapsulation, I.S. eliminates the ignition source from the ignition triangle. This in turn eliminates the potential for explosions.

In order to standardize efforts to make electrical devices safe for use in hazardous environments–including prevention of unintentional explosions–safety standards have been developed. The major ones:

In the United States: National Electrical Code (NEC). In existence for over a hundred years, its official designation is ANSI/NFPA 70. NEC itself approves nothing and has no legal standing until it has been adopted by the authority having jurisdiction.

Internationally: International Electrotechnical Commission (IEC). Based in Europe and engaged in writing standards, IEC designs documents used around the globe. Little by little, IEC standards are making their way into the USA. For example, with some modifications, they may have been issued as the UL version of IEC standards.

In Europe in particular, the equipment used in hazardous environments is handled by European Union’s Directive 94/9/EC and later editions popular by the term ATEX. ATEX concerns equipment and protective systems intended for use in potentially explosive atmospheres. The purpose of the directive is to facilitate trade within EU by aligning the laws of the member states regarding the safety requirements for hazardous area protection.

Maritime: The International Maritime Organization has adopted the Regulation 10.10.4 which stipulates new requirments for firefighting equipment used on naval ships.

The intrinsic safe equipment manufactured at Savox is certified not only for North America (USA and Canada) but also for the ATEX zone and internationally for all countries which have adopted IEC standards.

Dimitar Apostolov

Subcribe to our blog

Be among the first of your peers to hear about the new products and solutions from Savox.